China: Hy-Line Sponsors 11th International Poultry Forum China

In July, the 11th International Poultry Forum China 2022 (IPFC) was held in Jinan, China. More than 600 experts, entrepreneurs, and representatives from the broiler and layer industry attended the event. This forum focused on “Sustainable Development of the Poultry Industry.” Bruce Zhou, China Regional Business Manager, gave a presentation on "Updated Progress of Layer Breeding." In 2020, China was the leading egg producer in the world, with 400+ billion eggs and 30+ million tons produced; China egg consumption per capita was 298 eggs, ranking fifth in the world.

Bruce Zhou, China Regional Business Manager, gives a presentation at the International Poultry Forum China.

Uzbekistan: Toshkent Parranda Upgrades Facilities

Since 2020, Hy-Line distributor Toshkent Parranda has invested USD 8 million in high-tech equipment and new production facilities, including an incubator with a capacity of 700,000 eggs, a new feed mill, and two new parent facilities with a capacity of 42,000 birds.

In addition, the company's new laboratory can test feed quality as well as complete tests like ELISA, blood count, vaccine activity, and other tests to monitor the immunity of birds.

With these upgrades, Toshkent Parranda can meet the demand of 5.5 million day-old chicks for annual sales in Uzbekistan and neighboring countries.

Toshkent Parranda's new feed mill (top) and hatchery (bottom).

UK: Feather Cover and Liveability Make Hy-Line the Breed of Choice

Lincolnshire producer Ivory Arden started free range egg production seven years ago with 32,000 birds and the operation, spread over four sites, has since quadrupled in size. She started using Hy-Line three years ago and she was so impressed with the birds' feather cover and liveability, that three of the four farms are now stocked with Hy-Line and Ivory is considering moving completely over to the breed.

“The feather cover has been excellent which is so important, particularly for free range when the birds are on show for all to see,” says Ivory. In fact, her great-looking birds have been featured in a previous calendar produced by the British Free Range Egg Producers Association. Compiled from images submitted by producers, the calendar featured Hy-Line flocks in nine out of the 12 months!

“We’ve also found the Hy-Line very robust and it seems to bounce back from any challenges it has to face and this is reflected in the low mortality,” says Ivory. The farm’s first flock achieved a mortality rate of just 2.5% at depletion aged 78 weeks and Ivory has continued to enjoy similar results.

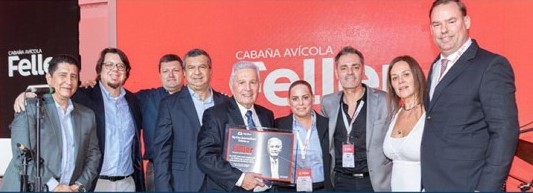

Argentina: Cabaña Avícola Feller Marks Company's 65th Anniversary and 25th Hy-Line Anniversary

Hy-Line and Cabaña Avícola Feller representatives recently gathered to celebrate the company's 65th anniversary and its 25 years as a Hy-Line distributor.

India: Srinivasa Farms Celebrates 5 Years of Partnership

During the technical school at Hyderabad on 21st November, Gustavo Wassermann, Hy-Line Commercial Director, gave recognition for completing 5 years distributorship to Suresh Rayadu, Managing Director,

Srinivasa Farms Pvt Ltd. (L-R) Suresh Rayadu, Managing Director for Srinivasa Farms, accepts a plaque commemorating Srinivasa's 5 years of distributorship from Gustavo Wassermann, Commercial Director for Hy-Line International.

South Africa: Hy-Line Partners to Provide Egg Protein to Malnourished African Children

South Africa, home to 60 million people is a country of extremes. It is a land of breathtaking scenery, eleven official languages, world famous National parks, ultramodern cities, but like so many countries in the world, it is plagued with extreme income disparity where a significant part of the population lives in abject poverty and suffers malnutrition. The World Bank determined South Africa to be among the most unequal counties in the world with 20% of the population living in extreme poverty with income of less than $2 per day. Poverty and poor health outcomes go hand-in-hand. Unicef attributes 11.4% of deaths in South African children under five to low body weight. Three out of ten children are stunted, a condition which affects their growth and development (Unicef South Africa). Malnutrition contributes to the vicious cycle of poverty. This story is in no way unique to South Africa but present worldwide to differing degrees.

With this as the backdrop, Hy-Line International approached Dr. Jim Blessman of Blessman International located in the one of the poorest areas of South Africa in northern Limpopo State. Twenty years ago, the Blessman and his family left the comforts of a successful medical career in suburban Des Moines, Iowa, USA, drawn to this remote part of the world to undertake the challenge to feed and improve the overall well-being for African children. Through many trials and obstacles, the Blessman’s organization has grown today to feed some 60,000 children via ten food distribution hubs in the country. Seeing ‘our neighbor’ at work in South Africa, Hy-Line International together with Hy-Line South Africa reached out to Dr. Blessman to cooperate with his feeding program with the purpose to add ‘an-egg-a-day’ to the feeding program to further enhance his efforts by enhancing the nutritional content of the meals. Blessman provides daily meals consisting of a basic grain and vegetable-based diet that the kids receive from Meals from the Heartland, also from Des Moines, which are shipped in container loads over several times per year. As a medical doctor, Dr. Blessman was well-aware of the health benefits associated with egg consumption and was eager to add ‘an egg-per-day’ to enhance the protein and vitamin content of his existing rations.

(L-R) Dustin Blessman and Dr. Jim Blessman at their South Africa facility.

One egg contains 6 grams of protein, 5 grams of healthy fats, 80 calories all while providing:

- Vitamin A: 6% of the recommended daily allowance (RDA)

- Folate: 5% of the RDA

- Vitamin B5: 7% of the RDA

- Vitamin B12: 15% of the RDA

- Vitamin B2: 15% of the RDA

- Phosphorous: 9% of the RDA

- Selenium: 22% of the RDA

- Eggs also contain amounts of vitamin D, vitamin E, vitamin K, vitamin B6, calcium and zinc

The immediate plan is to run a small pilot ‘proof of concept’ program in which Hy-Line International, Hy-Line South Africa and Blessman International cooperate to provide a minimum of one fresh egg per day to his local feeding hub starting in early 2023 from a flock of Hy-Line Silver Brown ready-to-lay pullets. Phase one of the project will be to establish a robust, scientific study to track the health outcomes of a small cohort of children at Blessman’s nearby Mokopone location with the assistance of US medical professionals with oversight from a South African medical organization into mid-2023. After this ‘practice run’ at which time we are confident that the study is sound, we will launch the official study with an unreached group of children to provide the meal rations plus an egg-a-day from the flock to track and document well-being outcomes. We anticipate this study will finish by mid-2024 at which time armed with scientific data, we will endeavor to upscale the program to bring the benefits of egg consumption to a much larger population to add egg protein to Blessman’s wider 60,000 child feeding program.

Hy-Line International and Hy-Line South Africa will place the started Hy-Line Silver Brown pullets in January 2023 which will result in eggs in a matter of a few short weeks while offering technical support and advice for best practices to maximize yields from the flock. The project will lean on the expertise of Mr. Bruce Dooyema of Versova Egg company in Iowa, one of the largest egg producers in the US, who is consulting to assure success with the project contributing his vast knowledge and prior experience in Africa on similar projects. We look forward to further develop this project over the next years to improve the lives of under-nourished South African children and demonstrate the power of the egg as part of the solution to reduce world hunger and improve overall health outcomes worldwide.

(L-R) Brittney Roorda, Bruce Dooyema, Dr. Jim Blessman, and Tom Dixon meet at the Hy-Line offices to discuss the “Egg-a-day" program.

|