| El Salvador: Criaves Celebrates 40 Year Anniversary with Hy-Line

Hy-Line is proud to recognize 40 years of distribution partnership with Criaves S.A. in El Salvador. Criaves’ chick quality meets and exceeds world market standards with some of the world’s best results in Central America with the W-80 and Hy-Line Brown. With the largest hatchery in Central America, Criaves and Hy-Line began its relationship in 1981. See the video of the award presentation here.

Hy-Line President Jonathan Cade (left), and Tom Dixon, Hy-Line Director of Breeder Sales to the Americas & Product Manager (right), present an anniversary plaque to Jorge Jiminez, Criaves Poultry Director (center).

Saudi Arabia: Hy-Line Team Attends Middle East Poultry Expo Saudi Arabia: Hy-Line Team Attends Middle East Poultry Expo

Hosted in Riyadh, Saudi Arabia, members from the Hy-Line team attended the Middle East Poultry Expo from March 14 to 16, 2022. More than 200 customers visited the booth for business discussions and to ask technical questions.

The Hy-Line Team in Riyadh

Botswana: First Chick Delivery Since 2020

The first shipment of Hy-Line Brown Layers produced in Hy-Line Africa in Zambia was delivered to Treasureland Farms in Botswana in April 2022. The Regional Business and Technical Manager Sujeewa Loku Waduge accompanied the chicks in a small, chartered plane. The Director of Treasureland Farm, Mrs. Letsile Wanita Kgoladisa received the chicks at the airport. This has been a monumental step toward strengthening regional supply of Hy-Line in Africa.

(L-R) Director of Treasureland Farm, Mrs. Letsile Wanita Kgoladisa, receives the chicks from Sujeewa Loku Waduge, Hy-Line Regional Business and Technical Manager, upon their arrival in Botswana.

China: Huamei and Hy-Line Continue 36-Year Partnership

Shenyang Huamei Livestock and Poultry Co was the first enterprise in China to import Hy-Line International grandparent stock. Since 1985, it has experienced the rapid development of the China layer industry, and grown its partnership with Hy-Line.

UK: Family Achieves Top Results with Hy-Line Brown

A committed family team and attention to detail is yielding top results for Daniel and Trudi Bates, now on their fifth flock of 32,000 Hy-Line birds on their farm in Mid-Wales in the UK.

The decision to enter into free range egg production was driven by Daniel wanting to give up his ‘day job’ as an agronomist and concentrate on running the farm. “At the time we were running 800 breeding sheep as well as rearing calves for beef production and I was trying to juggle that with a job that took me off the farm in the week,” recalls Daniel. “As you can imagine it left very little time to spend with Trudi and our three boys and I wanted to address that.” In common with many livestock farms in Wales, the addition of a poultry enterprise has helped to secure the viability of the holding and despite a squeezing of margins since the Bates started, Daniel has no regrets. “We borrowed a lot of money to do it and of course that’s a concern with input costs increasing like they are but from a lifestyle point of view it’s been a good decision.”

Undoubtedly helping Daniel and Trudi to ride out the current downturn in profitability is the consistently good results achieved from their flocks. Having done their research in the shape of weighing-up information from those already in the industry and comparing the different breed traits, the Bates opted for Hy-Line and have stuck with it ever since, with the last three flocks being Hy-Line Plus to help them meet their packer’s demand for larger eggs.

The flock that left the farm at 74 weeks last year achieved 354 eggs-per-hen-housed, a figure boosted by a mortality level of just 1.84%. Combined with an egg weight that reached 65g in late lay, total egg mass was 22.5kg, achieved on an average daily feed intake of 123g. With the current flock following a similar course – at 36 weeks they’re laying at 96% and 64g average egg weight with mortality a mere 0.2% – there’s no hesitation about re-ordering Hy-Line, with Daniel and Trudi further encouraged by the ease of management of this latest flock. “Even in the short time we have been doing it, we have seen the progress in genetics and we like what we are seeing now. In the past, at times it has felt that we have been working for the birds but now they’re working for us and we’re spending less time in the shed, “ says Daniel, who nevertheless still puts in a good shift, arriving at the poultry house at 5.20 each morning, except for lambing time when Trudi picks-up the early morning role and Daniel heads for the sheep shed.

There’s no doubting the flock performance being achieved is due in no small part to the hard work and commitment from all members of the family including boys George, Stanley and Oscar, aged 7, 9 and 10 respectively, who are never happier than when helping on the farm, with Daniel joking that the lighting times for the flock are governed by what time the school bus gets in! Along with their two cousins, they are willing helpers when it comes to picking up newly housed pullets and placing them on the aviary system at lights-out during the first week after housing, which, says Daniel, involves perhaps two nights of what he describes as heavy lifting with rapidly decreasing numbers over the following nights.

Prior to housing new pullets, the Bates team undertake the four-week turnaround themselves with Daniel in the chicken house spraying for red mite as soon as the previous flock has been removed. Controlling mite is something high on Daniel’s agenda. “We don’t want to be placing pullets in a house where they are immediately met with a mite infestation so the first job, whilst the house is still warm and before the mites begin to withdraw into cracks and crevices, is to spray the house, including taking the end caps off the perches and spraying inside there,” says Daniel, who then uses two doses of fluralaner during the life of the flock to help keep them mite-free. After spraying for red mite the next job is muck removal followed by a blowdown using a hired industrial compressor.

Stepping-up for muck removal is Oscar on a mini-digger. “He’s surrounded by some very expensive equipment and he doesn’t even nudge it,” says a proud Daniel, who then spends some long days on a pressure washer which sees the house washed and disinfected by the end of week three. “Week four used to be reserved for a holiday but that seems to have slipped by the wayside and is now spent on maintenance and any last-minute jobs,” says Trudi resignedly, whose mum Beryl collects eggs each day once the birds are in lay, with Daniel’s mum Buddug also lending a hand.

The Bates are meticulous when it comes to walking the birds and during nest training the flocks will be walked almost constantly from early morning up to lunchtime. “Walking birds has always been part of our life,” says Trudi. It’s a strategy that seems to work with peak daily floor eggs for the current flock of 32,000 amounting to less than 700 and at 36 weeks they are under one per cent.

India: Srinivasa Farms Recognizes Two Producers for W-80 Performance

Srinivasa Farms, the Hy-Line distributor in India, recently recognized two of its commercial producers for their success with the Hy-Line W-80. Both farms serve as models for prospective customers.

Eggceptional Poultries Farms in Hyderabad, and D S P Poultry Farm in Guntar have partnered with Srinivasa for over four years, and only produce eggs with the W-80.

Hy-Line Customer Anniversaries

Thailand: Charoen Pokpand Food Public Co, Ltd. Celebrates 5-Year Anniversary with Hy-Line

Charoen Pokpand Food Public Co., Ltd. is the one of the top 10 egg producers in the world. To present its first anniversary with Hy-Line for five years of partnership, President Jonathan Cade and Director of Southeast Asia Ron Gooi visited the CP Tower office to present the plaque. .

Hy-Line President Jonathan Cade and Southeast Asia Director Ron Gooi celebrate with team members at Charoen Pokpand's CP Tower office.

Korea: In-Person 35th Anniversary Celebration for Korean Poultry

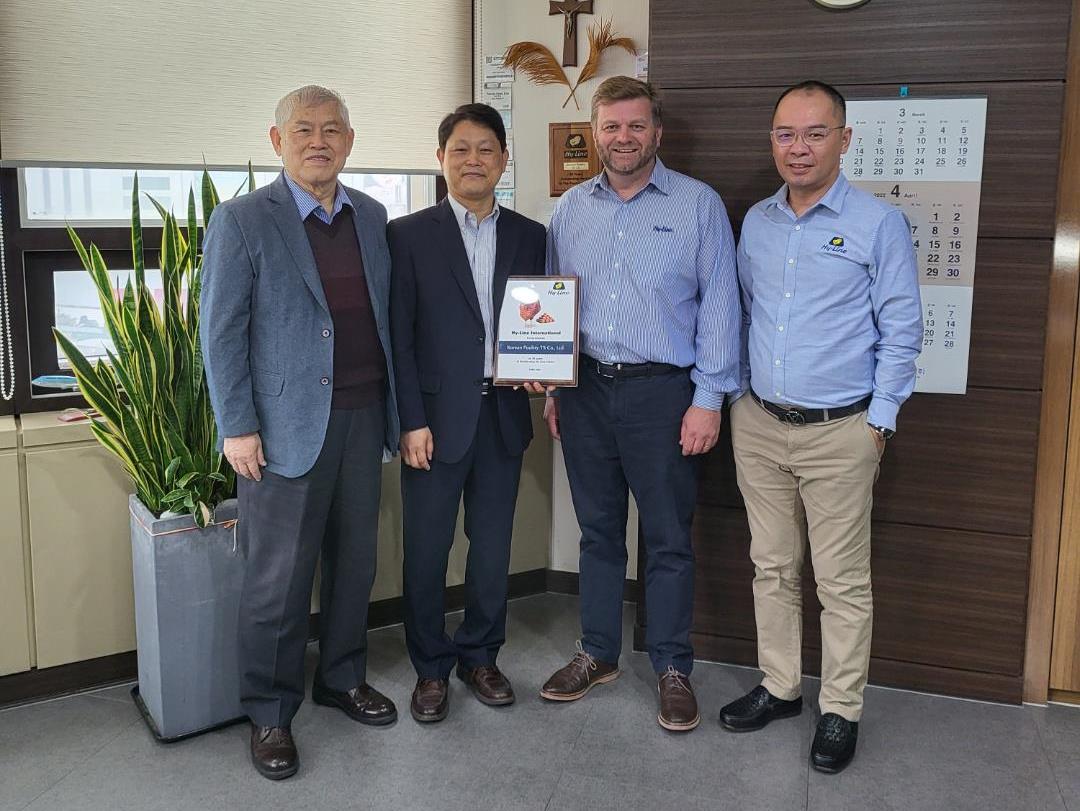

Korean Poultry Co. celebrated its 35-year anniversary with Hy-Line in person! President Jonathan Cade and Director of Southeast Asia, Ron Gooi, presented the plaque to President Mr. Yun-ho Kim and Chairman Younghwan Kim in the Seoul office. Korean Poultry Co. is the largest commercial chick producer in Korea.

(L-R) Chairman Younghwan Kim, President Mr. Yun-ho Kim, Hy-Line President Jonathan Cade, and Southeast Asia Director Ron Gooi.

France: Hy-Line France Celebrates 15 Years

Since 2004, Hy-Line France has been distributing day-old chicks to Hy-Line customers in Europe. Christopher Latimier, PS Production Manager, accepted the plaque in 2022.

Christopher Latimer, PS Production Manager for Hy-Line France, displays the 15-year anniversary plaque.

|